Rapid Prototyping

Once we complete designing (CAD) & CAE, for Product Development prototypes are needed. Rapid Prototyping is used to meet the following requirements:-

- Concept modeling

- Design verification

- Prototypes to validate Fit, Form & Function

- Master patterns for Vacuum Casting

- Master patterns for Investment Casting

- Prototypes for marketing and sales presentations

SLA - Stereo Lithography Apparatus gives output in Epoxy

SLS - Selective Laser Sintering with output in Nylone, Elastomer, Plystryrene

FDM - Fused Deposition Modeling produces ABS,PP,PPSF

3D Printing - Concept Modeler builds in Silica Sand, photopolymers etc

Suitable For

1. Jewellery |

|

|

2. Shoe

|

|

|

3. Architecture

|

|

|

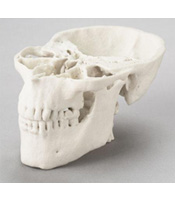

4. Medical

|

|

|

5. Electronics/Electrical

|

|

|

6. Toys/Mock Ups

|

|

|

7. Automotive

|

|

|

8. Customers Goods

|

|

9. Education

|

|

Room Temperature Vulcanization (RTV) or Silicone rubber molding is used in vacuum casting the fastest way to create limited batch of prototypes at an affordable cost. 3D Parts with undercuts and difficult shape can be easily fabricated.

Generally Polyurethane (PU) material is used for this purpose. ABS, Glass filled ABS, Acrylic, PE, PP,PPSF Elastomer etc PU material can availed for numerous requirements.

The above castings of PU material can be machined, glued, sanded, painted.

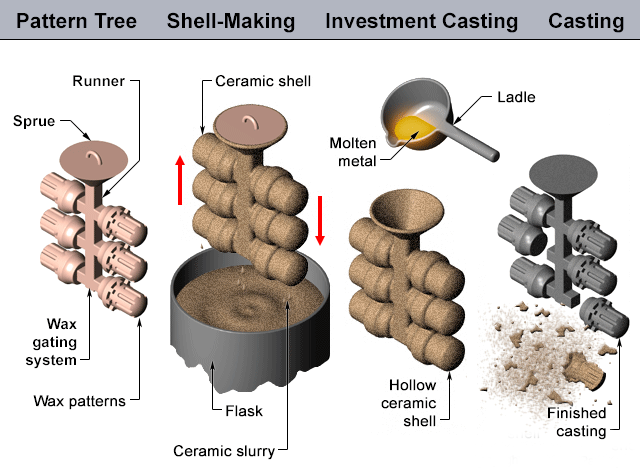

Investment Casting

Generally Polyurethane (PU) material is used for this purpose. ABS, Glass filled ABS, Acrylic, PE, PP,PPSF Elastomer etc PU material can availed for numerous requirements.

The above castings of PU material can be machined, glued, sanded, painted.

|

|

|

|

Examples of Investment Castings

TTIA Cad-Cam Infotex,

Regd. Off. : A-3/28, Ground Floor, Sector-16, Rohini, New Delhi-110089

Office. : J 220, Sector-2, DSIIDC Industrial Area, Bawana, New Delhi-110039

MOBILE: 9717467137, +91 9717564927

E-MAIL: info@ttiainfotex.com

Web.:http://www.ttiainfotex.com